Acetone-Furfural Resin

Alias: F14 Carbon/Carbon (C/C) Composite Resin, Furan Resin

Physicochemical Properties:

Furfural acetone resin is a new type of environment-friendly high temperature resistant resin with a high carbon value. It is a dark brown viscous liquid with a carbon residue value as high as over 60%. It is a composite impregnated resin with very good acid/alkali-resistant properties and an impregnated carbon fiber reinforced carbon matrix.

It can produce a material of carbon/carbon (C/C) composite which is able to resist a high temperature over 2100℃- 3800℃. Its density is higher than 1.3g /cm3, and its stress intensity is 5 times higher than a high temperature alloy. long life-span and high stress intensity (5 ~ 7 times of metal based material).

Once the Furfural acetone resin applies with an acid curing agent, it can be transformed into an insoluble and infusible polymer under normal temperature. The polymer can resist a temperature as high as 450-450 degrees. It is widely used in impregnated graphite, carbon fiber products and manufacturing graphitic carbon fiber high-temperature resistance and corrosion protection components.

Quality Standard

|

Name of indicator

|

FA-1 Type

|

FA-2 Type

|

|

Appearance

|

Dark Brown Viscous Liquid

|

Dark Brown Viscous Liquid

|

|

Viscosity (25℃) s

|

100-2000

|

12-100

|

|

Water content, % ≤

|

2

|

1

|

|

|

|

|

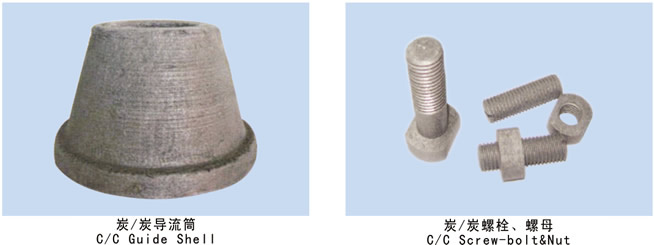

Uses:It can be used to produce C/C composite materials, graphite products and carbon-fiber composite materials, fiber reinforced plastics, laminated boards and acid proof corrosion resistance adhesives. Laminated board products can be used as chemical anti-corrosion pipes and lining of storage tanks. The C/C composite material has good wearability. It can be used as brake-pairs of airplanes, brake blocks of automobiles and fire-proof materials. The resin can be used for impregnation of porous materials such as graphite, ceramics, asbestos and carbon fiber. It can be used to make rocket parts, C/C sheet materials, hardened thermal preservation felts, C/C thermal field materials for polycrystalline silicon hydride heating furnaces, heat insulation shields, carbon/ceramic bearing, C/C nozzles, C/C ablation resistant materials, C/C heaters, C/C gliding block of magnetic suspension, and C/C pantograph of electric locomotives. In the presence of an acid curing agent, the resin can be transformed into an insoluble polymer. After curing, it is able to bear a temperature of 450 – 500 under normal temperature, and become a chemical resistant and fire resistant composite material with high stress intensity. It is widely used in impregnated graphite and carbon-fiber composite products and producing graphitic carbon fiber high-temperature resistant corrosion protection parts. The resin can be used to modified epoxy resin for protective coating of ship propellers and sea pollution resistant coatings.

Formula: a two-component resin and curing agent. Proportion: 100 parts of resin: 2-15 parts of curing agent. First, put the resin into a container and add into the curing agent slowly and stir well. Adjust the amount of curing agent according to the curing time.

Packing:in 250kgs steel drum net each.

Storage and Transportation: avoid direct exposure under the sun, and store in dry and cool place.

Factory Address:North Industry In Wuji County area, Shijiazhuang City , China

Working Address:2701,Tower A-1,Shidai Ark,No.336 Heping East Rd.,Shijiazhuang China

Phone:+86(0)311-86683938

Fax:+86 (0)311-86682938

E-mail:furfurals@163.com

furanss@163.com

flfa@heinfo.net

http://www.furfuryl.com